ABOUT US

ABOUT US

KESSLER accompanies the product from the electrical and mechanical construction, to the numerical calculations using the finite element methods and analytical calculation programs to the testing, commissioning and parameter optimization of the end result. KESSLER motors meet the highest efficiency requirements.

components to the on-site service

Founded in 1923 by Franz Kessler, the company has developed to become the leading supplier of motor spindles as well as directly driven 2-axis heads and rotary tilt tables for the machine tool industry. KESSLER is proud to list many major companies from the mechanical engineering sector amongst its long-standing customers.

With the expertise of almost 100 years, KESSLER is continuously developing and optimising its products. The KESSLER product range serves a wide range of sectors, processes and applications. Close cooperation with our customers remains our key focus. The extensive product range, from hightech spindles, 2-axis heads, rotary and rotary tilt tables to motors and direct drive systems, enables KESSLER to implement customised solutions with speed and flexibility.

Service is a matter of trust. Rely on us as your trusted service partner: KESSLER has an established global network of technology and service centres.

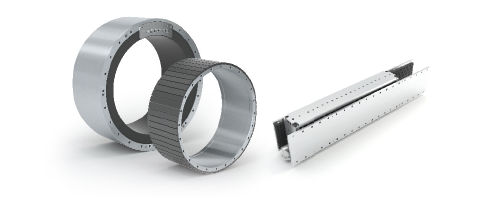

- Energy-efficient motors with top power density and degree of efficiency

- Short delivery times (within 6 weeks for products up to size 530, in current series production and with fixed lot sizes)

- Production at competitive prices for the global market

- Standard motors with minimized construction height and cogging torque

- Standard motors with 100 % installation compatibility

- Special motor assembly kits and motor assembly groups according to customer requirements

- Standard motor sizes up to a diameter of 3 meters

- Torque ripple less than 1 %

- Integration of any direct drive into any environment

- Applications for very high torque (KESSLER HTM and HTMx series)

- Applications for very high speed (KESSLER STMx series)

- Application examples: direct drive for sport motorboats, renewable energy applications, automotive drives and plant engineering

With almost 100 years of experience in motor technology, KESSLER energy designs and manufactures energy-efficient drives for every range of performance, in accordance with individual customer requirements.

| Torque [Nm] | Speed [rpm] | ||

|---|---|---|---|

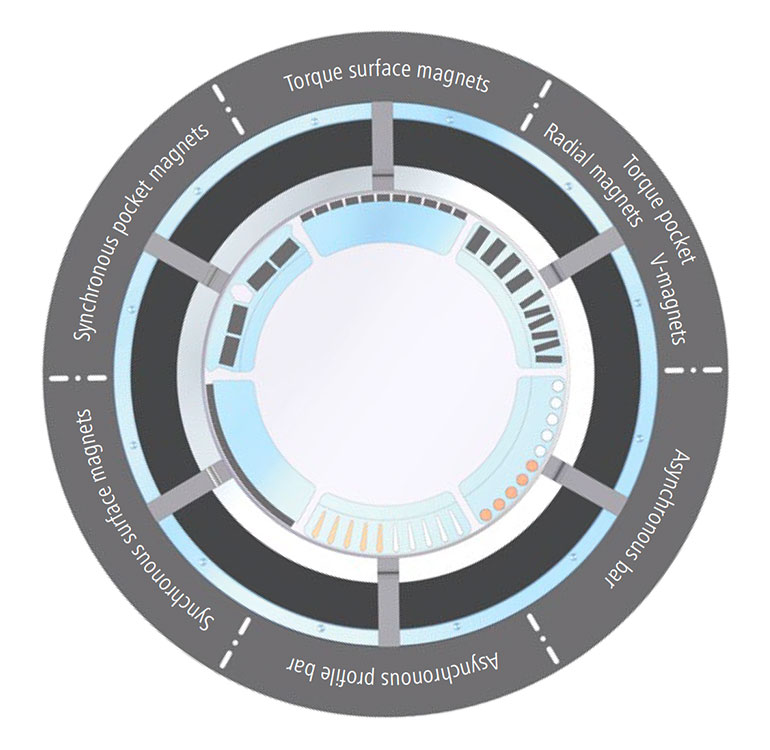

| Torque pocket, V-solenoids | Video |

||

| Torque radial pocket solenoids | Video |

||

| Torque surface solenoids | Video |

||

| Synchronous pocket solenoids | Video |

||

| Synchronous surface solenoids | Video |

||

| Asynchronous copper rod | Video |

||

| Asynchronous aluminium rod | Video |

||

| Asynchronous copper bar | Video |

||

| Asynchronous aluminium bar | Video |